Elastic Rings

Elastic Bands in Cast Iron, Bronze and Steel

Contact

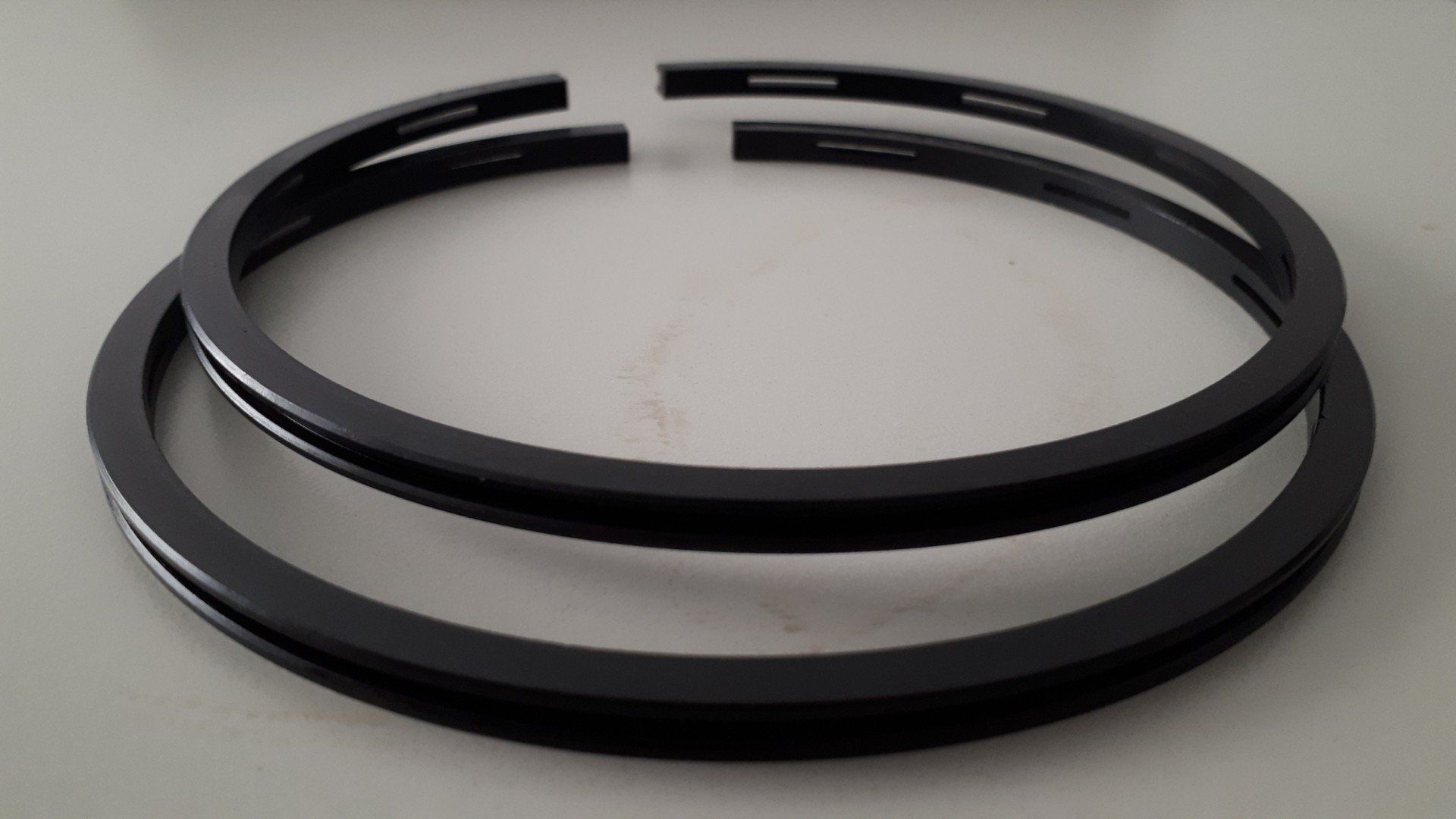

EL. TE. Segmentitalia is able to satisfy any request of elastic rings (compression or scraper) from a bore of 12 mm to a bore of 1800 mm.

The implementation is performed based on drawings and/or samples, or according to DIN/ISO standards.

The materials used range from special cast irons to segments of spheroidal and austenite cast iron, bronzes and steels.

These elastic bands are used in the field of compressor technology, pumps, presses, hydraulic cylinders and diggers.

Hydraulic and marine transmissions; industrial plants; chemical or metallurgical/steel maintenance; and spare parts

complete the range of our offer, where we can provide 360 degrees assistance with highly professional advice.

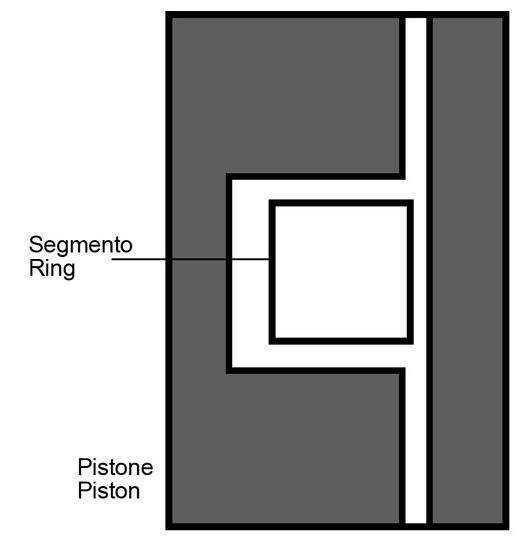

Elastic Ring Characteristics

The main characteristics that are required for the elastic segments are intertwined and can be summarized as follows:

• Maximum seal

• Excellent characteristics of elasticity, therefore elastic modulus allow the necessary tightness of the band and the ability to preserve it under the action of thermal stresses.

• Maximum and uniform wear resistance compatibly with the hardness of the cylinder, in order to form a perfectly smooth and uniform sliding surface in the segment.

• Surface condition in relation to the type of processing being conducted.

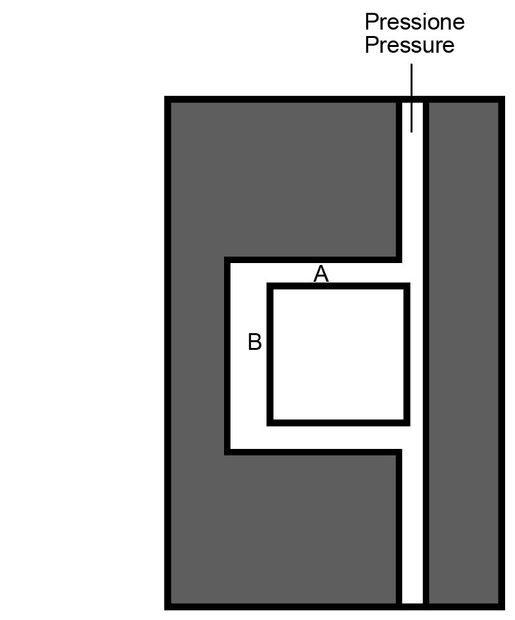

Maximum Seal

Under a dynamic point of view, the maximum seal is ensured, both by tension or elastic load of the ring, and by the pressure exerted on surfaces A and B of the ring by the gas or fluid present in the cylinder during the compression phase.

These characteristics must be accompanied by an adequate degree of work on the rubbing surfaces, in order to have the best contact with the cylinder wall and the maximum structural stability of the ring at all temperatures while inside the cylinder. The aforementioned characteristic of a perfect seal results in, firstly, better conductivity and heat dispersion to the lower parts of the machine and, secondly, a more uniform distribution of the lubricant on the sliding surfaces with consequent reduction of oil consumption.

Resistance to Dynamic and Thermal Stresses

The first requirement is that the two products are linked one to the other. In fact, it is an essential condition for the use of the ring that the initial state of perfect sealing is retained for as long as possible. In order to achieve that, the value of the elastic modulus of the cast iron must not decrease. As a matter of fact, such a situation would end up in a loss of elasticity that would damage the initial perfect sealing. These conditions and requirements are met only by using a material with a completely pearlitic structure containing stabilising elements of the aforesaid structure that are able to resist under the effect of thermal stresses. Before the final phase of mechanical processing, an appropriate heat treatment eliminates the residual stresses of the material and adjusts its elasticity characteristics.

Closure rings, also called scrapers (i.e. rings with an internal seal on a shaft/rod or roller) are realised.

Materials used for this procedure: special cast iron, bronzes and steels.

Fill out the contact form and ask for more information about elastic bands in cast iron, bronze and steel

ContactEL.TE. SEGMENTITALIA SAS

Via Francesco Nava 15/17 – 20159 Milan, Italy

FAX/TEL. +39 02 6071598 TEL. +39 02 6080105

VAT Reg No. 11013830150 | Legal Information | Privacy Policy & Cookie Policy