Production of PTFE Elastic Bands

There is vast literature on PTFE (polytetrafluoroethylene) which is present in all countries of the world under various registered names: Telfon, registered by Du Pont (USA); Fluon, registered by ICI (GB), Algoflon registered by Montedison (I), Hostaflon registered by Hoechst (D). This literature is mainly focused on loaded PTFE, which proved to be more suitable in some fields of employment, especially mechanical.

Researchers, along with different methods of molding and sintering, experimental realisations, and important moulding complexes based in Italy, have shown not only the wide range of use but also the possibility of solving apparently insoluble problems. Only certain technicians of specific sectors could express their opinions and their ideas on possible changes, in order to achieve improvements and lower costs.

Elastic Rings Made of Loaded PTFE

In these brief notes we wish to examine elastic rings made of loaded PTFE. They are used on hydraulic and pneumatic units, in things like presses, knives, tipper trucks, hydraulic cylinders and pneumatic tires of various sizes, compressors, and more. Carbographite chargers have been in use for many years in dry compressors. Until 1975 these devices were equipped almost entirely with cast iron rings. Some years ago, an interesting publication by ICI underlined the belief that the industry could progress only through a free exchange of technical know-how among producers. Many of the major manufacturers of compressors, hydraulic units and elastic bands already carried out research and development work on their own to further evaluate the performance of the elastic bands.

The Advantages of the Loaded PTFE Elastic Rings

At this point we ask: which kind of advantages – in terms of performances, duration, costs – has the recent adoption of PTFE loaded elastic rings produced?

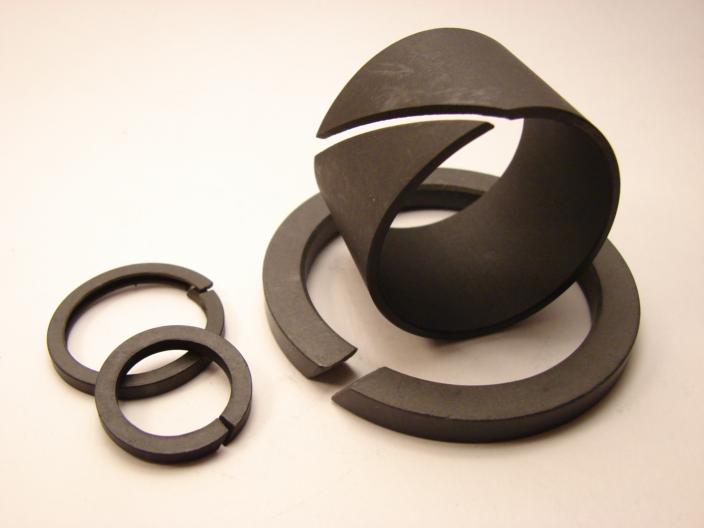

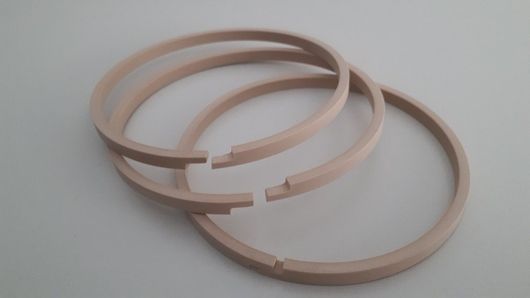

On what aspects we can agree and what criticisms can we move? The piston elastic ring – be it in cast iron, bronze, loaded PTFE and with expanders – is not a gasket but a mechanical tool subjected to the wear and tear of linear and rotation speeds; to lateral thrusts of the alternating motion; to pressure; to high temperature; to chemical aggression etc. In order to offer a real guarantee, it must be produced by technical groups and producers with considerable experience with motor and hydraulic applications. Hence the work of EL.TE SEGMENTITALIA for this application. However, with the exception of these rings (which are covered by a patent), the elastic PTFE band made with an appropriate blend is not subject to breakage or seizure, a positive fact to note. Its deformability is conditioned by a uniform pressure – i.e. supplied by an expander that presses with equal intensity into the inside of an elastic band (which is very difficult to obtain with a flat section of calendered steel as in old conception) - and therefore the adhesion of the segment to the cylinder is excellent and with a very low coefficient of friction. The temperature at which PTFE works is within 250°C. As for the ring's cut, in addition to the traditional straight cut, the oblique cut, and the bayonet style cut, there is also an inclined bayonet style cut. Still, our preference is directed to the swallow type (FIG.1) which ultimately closes a ring created open.

We also had the opportunity to see an elastic band consisting of a 6 × 6 section ring with a 2 mm step. and an additional ring inserted in it with the purpose of closing the passage between the tips (FIG.2). However, we do not recommend it for small diameters, also due to assembly difficulties. In fact, if there are holes in the cylinder that don't have a diameter around 6-8 mm, the ring does not dwell on the holes, especially if there is a high pressure in the cylinderand. As such, we do not suggest this solution for all other cases. We appreciate the static seal achieved by cone machining. The PTFE integrates perfectly with the sliding function. This function does not allow the cylinder to come into contact with the piston. The thickness of the skate varies according to the space existing between the cylinder and the piston and this in turn varies, depending on the material used for the piston. Naturally, all of this requires the collaboration between the manufacturer of elastic bands and the constructor of the hydraulic cylinder complex. We are indeed satisfied with this new orientation that has made new possibilities available to the designer. Therefore, in the study of these new possibilities, the choice of the mixture, that is the charge of PTFE, is of decisive importance.

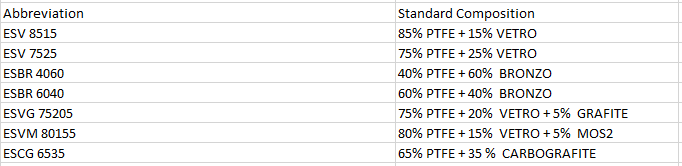

Referring to the literature of the producers of raw materials mentioned at the beginning of this meeting, we note that it is possible to have printed materials available for processing with the characteristics listed in the table (TABLE 1) which concern the different types of charge. It is certainly out of the question that loaded PTFE is the material that offers the best solutions and that is has a very modest friction coefficient. It is also known that PTFE incorporates different materials (including metal residues); that the wear and tear in relation to the roughness of the sliding surface is negligible; and during the sliding with some other materials there is a transfer of the first onto the seconds. This transfer, which unlike rubber, takes place without any hardening, settles between 18 and 22° C. The material responds perfectly at a speed of 5 m/sec and it remains unassailable by any atmospheric and chemical agent. All these characteristics justify the affirmation that loaded PTFE in its working environment – i.e. at temperatures no higher than 250 ° C – is perfect for designers of every field.

Elastic bands and guide shoes are made from tubes and rods in the following materials:

VIRGIN PTFE AND ITS LOADS:

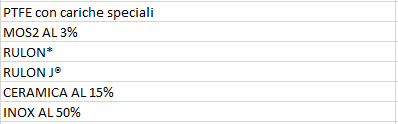

Guide rings and elastic segments are also made in

PTFE with special fillers:

In POLYAMIDES and for heavy duty, high temperatures and operating conditions particularly difficult in:

VESPEL®

PEEK®

PEEK CARICATO®

TORLON®

TECHTRON®